Motion X Gear-trains

We are proud to present a custom gear-train conceptualized to supersede the performance of any conventional power-transmitting-mechanism by using a new approach concerning the gear's design.

Patent granted in US and Canada under "Gear set in which interacting gears have a different circular pitch".

United StatesPatent# US 11,333,221 B2

Canada Patent# CA3076440.

Every conventional gear-set is designed to be in compliance with some rules in order to avoid improper mesh of the teeth. They all need to have the same circular pitch on both gears, need to have the same tooth shape on both gears and need to follow the gear module. These rules cause many disadvantages such as restricting the number of teeth combinations available for a given size gear-set. Therefore limiting the speed ratio's and the tooth thickness availabilities for a given physical size of gearbox, consequently the pushing force of the drive tooth is always applied to the driven tooth in a perpendicular manner as the meshing teeth slide along each-other.

The types of gear-sets we offer do not comply with any of these rules. Although in order to provide fluent meshing between the teeth, it is necessary to use a different pushing force angle than perpendicular. In terms providing more available options on the speed ratio and on the tooth thickness. They can operate at other speed ratios than the conventional gear-set and thicker tooth size can be used for the same rated size conventional gearbox, offering a wider range of application and a better reliability.

After conducting many experiments on different prototypes and comparing both gear-train types, we realized that a superior efficiency over the conventional systems is also achieved. The other pages on this website elaborate on this subject.

The custom gear-trains are especially conceived to decrease fuel consumption of engines such as in automobiles, mobile equipment and small engines. Furthermore they can also amplify power generating capacity in power plants by adding the gearbox between the turbine and the generator, or be used to reduce energy consumption of an industrial facilities when replacing the conventional gearbox with the custom gearbox. In fact a 12% increase in efficiency occurs when integrating the custom gear-train into any type of power transmitting mechanisms.

Visit "Operation Basics" page for a detailed description on how it works.

We presently only have prototypes fabricated and are seeking for investors to bring this invention to the next level. We are prepared to perform a live presentation free of charge and demonstrate how the gearboxes are providing a 12% increase in power. This is a great opportunity for investors in the energy sector!

The demos presented on this website are patented in the U.S.A and Canada and cannot be manufactured without our consent.

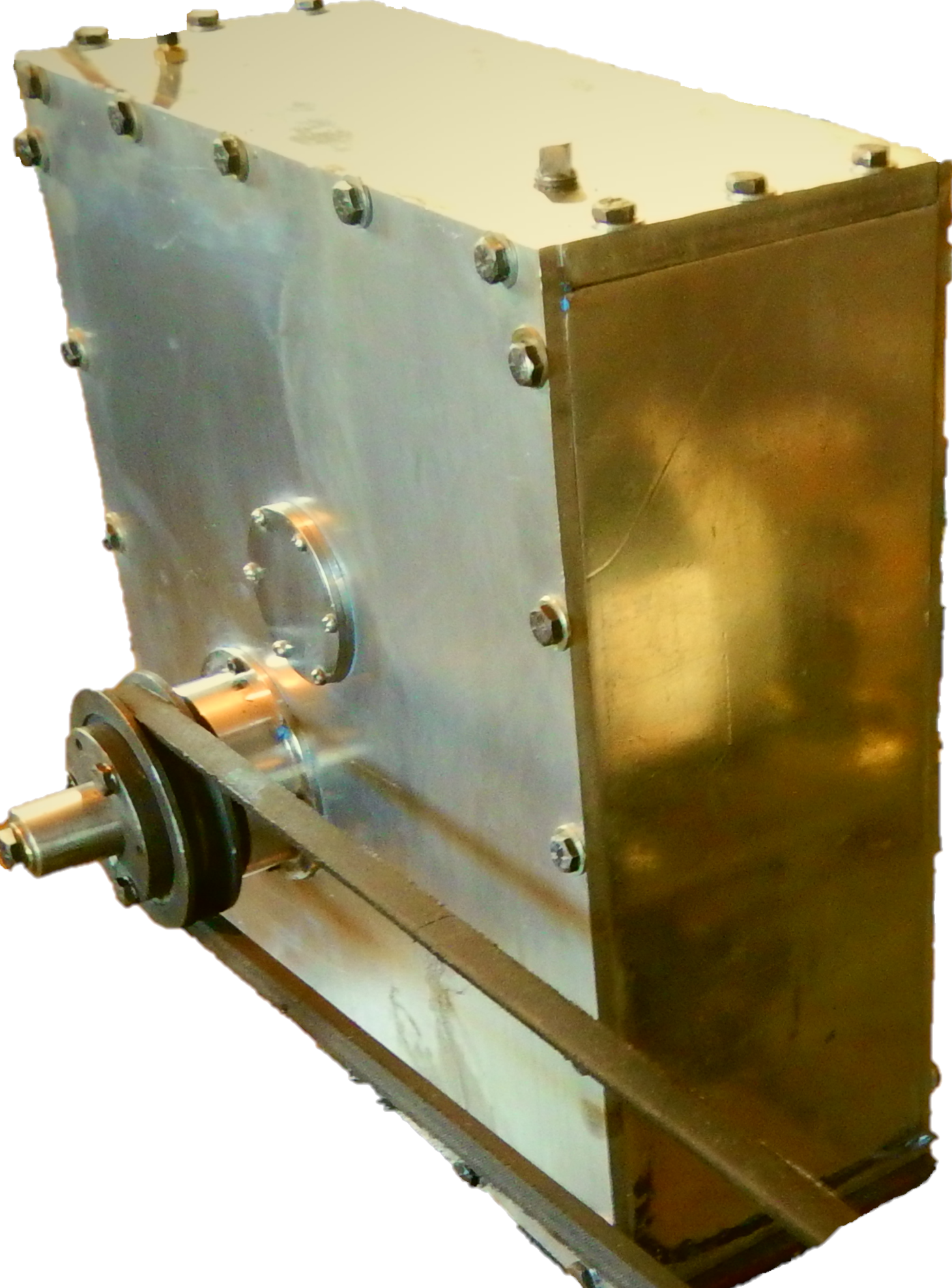

THE SPUR TYPE MOTION X GEARBOX:

NEW GEAR-TRAIN DESIGNED TO INCREASE PERFORMANCE

GEARBOXES/ SPEED REDUCERS

Motion X Gearboxes are available for parallel axle, nonparallel axle, intersecting axle and non-intersecting axle arrangements.

- Speed ratio from 1.0 to 115.9

- Horsepower from 1 to 2700 HP

- Input speed from 11 to 1750 rpm

- The specially formulated gear-sets are designed to provide a better performance, bigger gear tooth and bigger bearings/shafts when compared to a common gear-train having the same rated size.

- A smaller power source can be used to provide the same output torque, HP and RPM than a same rated size conventional gear-train.

- We also offer a special gear-train having a 1:1 speed ratio designed for automotive which adapts to the vehicle's driveline and reduces fuel consumption by up to a 12%. The same design can also be used in power plants, installed between the turbine and the generator and increase power generating capacity by up to 12%.

Be part of the climate change solution, the energy crisis solution and help to reduce pollution.

Check out the other pages where the Custom Mechanisms are compared to the Conventional Mechanisms, and also for a full description on how they operate.

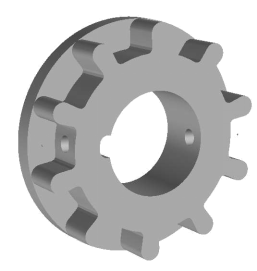

The Input Gear;

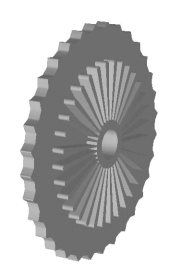

The Output gear;

The Idler (Main) gear;

Free Consultation or Book appointment

Contact us at; mechalldon@gmail.com